Artificial intelligence (AI) plays an important role in shaping the future of technology and society. With the ability to process massive amounts of data, and understand and interact with humans naturally and intelligently, AI is opening up many new doors for thriving fields.

The Development of AI in technological fields

According to a 2023 report by the McKinsey Global Institute, it is estimated that AI technologies could help increase global GDP by up to $13 trillion by 2030. This highlights the immense potential of AI applications in businesses and industries.

A survey by the B2B market provider Xometry Inc. also found that 70% of companies have deployed at least one AI application in their business operations. The leading industries in AI adoption include finance, retail, healthcare, and technology. Notable examples include Alibaba using AI to personalize online shopping experiences and improve demand forecasting; Netflix using AI to recommend relevant content for each user; Spotify using AI to analyze music data and suggest new songs for user; and Amazon using AI to optimize logistics and delivery processes.

The potential of AI in the semiconductor industry

Generative artificial intelligence – The new trend in the semiconductor industry

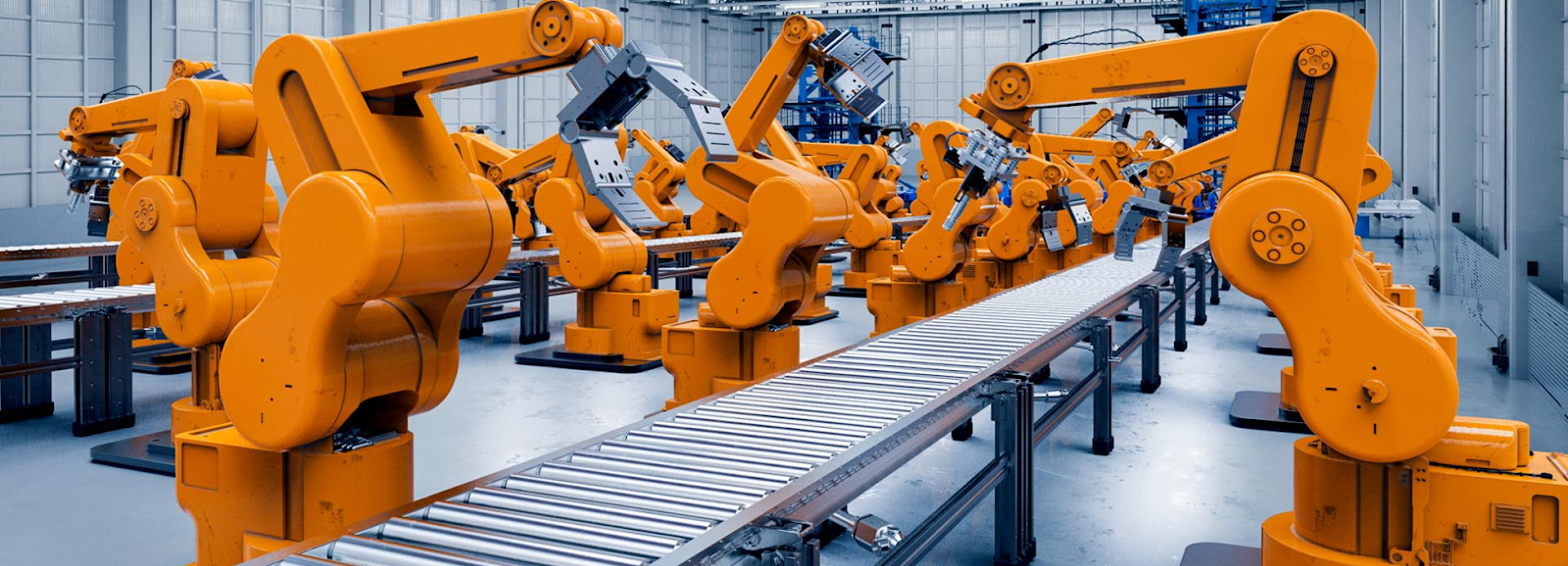

In recent years, we have witnessed the explosion of artificial intelligence (AI) and machine learning technologies, opening up new opportunities for various industries. The semiconductor industry, with its high-tech nature and demand for precision, is one of the fields that is benefiting greatly from the development of AI.

The applications of AI in the semiconductor industry are becoming increasingly widespread, from using models to optimize chip design, to applying machine learning for quality control in the manufacturing process. These technologies allow semiconductor manufacturers to achieve higher accuracy and efficiency, as well as optimize processes to minimize costs.

The potential of AI in the semiconductor industry is still vast. With the ability to analyze massive amounts of data, AI can help manufacturers predict and prevent quality issues, while also optimizing operating parameters to improve performance. Additionally, AI can be applied in other steps such as material selection, production planning, and supply chain management, enhancing the competitiveness of semiconductor businesses.

With these promising applications, AI is becoming a new and greatly-anticipated trend in the semiconductor industry. Successfully leveraging these advancements in this field will bring many benefits to manufacturers, from improving product quality to increasing productivity and manufacturing efficiency.

The potential applications of artificial intelligence in the semiconductor industry

Artificial intelligence (AI) technology is being increasingly adopted in the semiconductor industry, bringing significant potential to accelerate and enhance the efficiency of activities across the value chain.

Most notably, AI is helping to accelerate and improve the efficiency of chip design. Learning models can analyze large volumes of design data to optimize technical parameters, thereby significantly reducing design time and cost – a crucial need as chip technology becomes increasingly complex. Moreover, AI is contributing to improving the quality and performance of semiconductor products. AI algorithms can automatically detect and remedy defects in the design and manufacturing processes, while also optimizing parameters such as performance, power consumption, and operating temperature.

In addition, the application of AI in semiconductor production also helps save a significant amount of cost and time. Thanks to the ability to automate processes such as quality inspection, production planning, and supply chain management, AI contributes to increasing the efficiency of the entire production process. More importantly, AI-generated semiconductor technology creates new opportunities for creativity and innovation in the semiconductor industry. AI models can automatically generate new chip designs, far exceeding what humans can do, leading to the emergence of entirely new technology applications and products.

With the great potential mentioned above, artificial intelligence technology is becoming a very popular and widely applied trend in the modern semiconductor industry.

Challenges of applying artificial intelligence to the semiconductor industry

Technical and technological challenges

Although artificial intelligence (AI) technology is increasingly being widely applied in the semiconductor industry, there are still many technical and technological challenges that need to be overcome. The increasing complexity of modern semiconductor chip designs is setting more stringent requirements for performance, energy efficiency, and advanced computing capabilities. Many AI applications such as natural language processing and computer vision require very large computing resources, requiring semiconductor chips to be able to meet this demand.

In addition, integrating AI technologies into semiconductor chip design and manufacturing processes also faces many challenges. Engineers need to ensure that AI models are developed and deployed effectively, ensuring accuracy, reliability and scalability. Moreover, the need for large computing power and memory to run AI models is also a significant challenge. Semiconductor chips must have the ability to process and store the massive data required for AI applications, while ensuring reasonable performance, energy efficiency and cost.

Issues of data, privacy and security

In the process of applying artificial intelligence (AI) to the semiconductor industry, the issues of data, privacy and security are becoming important factors that need to be prioritized. Developing effective AI models requires large and high-quality data sets for training. However, the collection, storage and use of this data, especially personal and sensitive data, must comply with user privacy and security regulations.

In addition, when AI is deployed in critical systems such as semiconductor design and manufacturing, security risks also become a major concern. Cyber attacks can affect the entire production process and cause serious damage.

To address these issues, the semiconductor industry needs to implement appropriate safety and risk management measures. This includes ensuring data security, implementing encryption and data protection technologies, and establishing strict access control and monitoring processes for sensitive data. At the same time, close cooperation between technology, privacy, and cybersecurity experts is necessary to build a safe and sustainable system that meets the ever-increasing demands of the semiconductor industry.

Leading companies applying artificial intelligence to semiconductor manufacturing

The rapid development of microelectronics technology has posed major challenges for semiconductor manufacturers. To maintain a leading position in the increasingly fierce competition, top companies like NVIDIA, Intel, and Samsung have proactively deployed artificial intelligence (AI) applications in key stages of the manufacturing process.

Specifically, NVIDIA is one of the leading companies in applying AI to semiconductor design and manufacturing. The company has developed AI platforms like NVIDIA Jetson, which enable the automation of many factory processes. Additionally, NVIDIA uses AI to optimize microchip design, aiming to improve the performance and computing capabilities of its chips.

For Intel, the world’s leading semiconductor manufacturer, it has also implemented various AI applications throughout its production process. The company has used deep learning models to optimize chip design, thereby improving the performance and features of its products. Intel has also applied AI to predict and detect defects in manufacturing, helping to increase productivity and reliability.

Notably, the South Korean giant Samsung Electronics has also deployed AI-based solutions to enhance the quality and efficiency of its production. The company has used AI models to inspect and detect defects on chip surfaces, allowing it to eliminate faulty products. In addition, Samsung has applied AI to predict potential issues in its factories, enabling timely preventive measures.

Leading companies like NVIDIA, Intel, and Samsung have recognized the immense potential of AI in improving production efficiency, product quality, and the competitiveness of the semiconductor industry.

Conclusion

With the initial successes in applying AI to chip production, the role of artificial intelligence can be expected to become increasingly important in the semiconductor industry in the coming time. Machine-based and deep learning solutions can help automate many important steps such as quality inspection, design optimization, and risk management, thereby helping to improve productivity and product quality.

To learn about the latest developments of artificial intelligence for semiconductors in the future, do not forget to follow the FPT Semiconductor news page to stay updated on the newest information!